Meister of Manufacturing Information Technology (MMIT)

Leader Training Program

IVI, together with IT Coordinators Association, a specified non-profit activity organization, responded to a public offering of Ministry of Health, Labor and Welfare, the project “Development of Meister of Manufacturing IT Leader Training Program” in 2017, which was applied for a public invitation “Project for the Development of Education and Training that Contributes to the Career Development and Productivity Improvement of Workers during 2017 to 2019”. IVI has been promoting the developed educational program as Meister of Manufacturing IT Leader Training Program Education in 2018 and 2019. IVI restarted the program as an IVI’s independent project in 2020. However, due to the spread of the new coronavirus infection, its recruitment and activities have been suspended.

[Purpose of the project]

The purpose of the project is to spread education and training widely through cooperation with industries. Its education and training is for manufacturing engineers who have formed their careers as engineers in the field of manufacturing, such as in machine manufacturing industry, to acquire the knowledge and skills necessary to plan, develop, and operate production systems utilizing advanced IT technology in order to realize the fourth industrial revolution in Japan in the future.

[Outline of the education and training program and the targeted human resources (Meister of Manufacturing IT)]

◆ What is Meister of Manufacturing IT?

- Human resources who can play a central role in the process of implementing a bottom-up kaizen-style system development based on manufacturing sites as the starting point, and implementing it step by step in their companies.

- Human resources who can enhance competitiveness of companies through manufacturing that maximizes the use of digital technology and data for production systems that are constantly evolving in co-existence with humans and machines.

- Human resources who can embody open and closed strategies to connect with production systems in other companies and regions in a borderless manufacturing business environment.

- Human resources who can see the flow of work as a flow of value, and who can design a new system for value creation made possible by replacing part of it with data using the IoT.

For reference: Program contents and Schedule

◆ Mastering and applying advanced IT implementation techniques

- Obtain data from existing equipment with IoT

- Use cameras to automatically record production status

- Use IC cards to manage production history

- Visualize remote factories using a cloud system

◆ Learning and applying system integration techniques

- Create a simple inventory management system

- Create a simple quality data management system

- Create a simple schedule management system

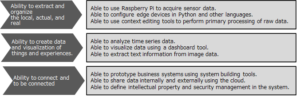

For reference: Examples of abilities and skills that can be acquired through the program